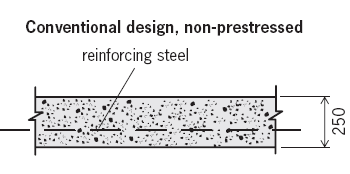

In the field of structural concrete construction, two basic concepts are generally applied in practice: conventionally reinforced and prestressed concrete. In conventionally reinforced concrete, ordinary un-prestressed reinforcing steel is integrated with the concrete matrix of a structural element such as a slab,

beam, column, or wall for the purpose of providing resistance to concrete strains and cracking. The reinforcing steel acts only when the concrete is strained under tension or compression as it is fully bonded to the concrete. In prestressed concrete, predetermined forces are imposed on the concrete structural member by special high-tensile steels prior to the members functioning as a load-supporting element. These preemptive prestressing forces are calculated and positioned to mitigate the anticipated stresses that subsequently occur during the service loading of the member, thus reducing the net final stresses developed and allowing a significant reduction in the required size of the concrete elements. Both conventionally reinforced and prestressed

concrete elements can be fabricated as precast units, which can then be integrated to form a structural framing system.

beam, column, or wall for the purpose of providing resistance to concrete strains and cracking. The reinforcing steel acts only when the concrete is strained under tension or compression as it is fully bonded to the concrete. In prestressed concrete, predetermined forces are imposed on the concrete structural member by special high-tensile steels prior to the members functioning as a load-supporting element. These preemptive prestressing forces are calculated and positioned to mitigate the anticipated stresses that subsequently occur during the service loading of the member, thus reducing the net final stresses developed and allowing a significant reduction in the required size of the concrete elements. Both conventionally reinforced and prestressed

concrete elements can be fabricated as precast units, which can then be integrated to form a structural framing system.

Construction methods. Over the past several decades, precast and prestressed concrete construction methods have produced considerable savings in materials, labor, and construction time. The reduction in required material quantities due to prestressing produces lighter-weight building

structures. Since gravitational and seismic loading forces are proportional to structure weight, a lighter weight building will enjoy additional reductions in

required structural sizes for all vertical and lateral force-resisting elements such as columns, beams, slabs, moment frames, shear walls, and foundation elements.

For high-rise buildings, a reduction in concrete sizes will also result in shallower structural concrete deck framing depths, which in turn will reduce the floor-to-floor height requirements and the overall height of the building structure. This will in turn reduce overturning resistance requirements under wind and seismic loading, while simultaneously lowering the cost of vertical elevator and stair shafts, mechanical and electrical risers, exterior façade cladding, and other vertical elements of construction. Prestressing usually is performed with special

high-tensile steels that provide maximum strength with a minimum quantity of steel, resulting in significant savings in steel tonnage and cost. Generally, the prestressing steel strength is approximately 4.5 times stronger than ordinary reinforcing steel, but costs only twice as much per unit weight as ordinary

reinforcing steel. Prestressing of beams and slabs is most economically applied in long-line precasting mass-production operations. Because of the inherent efficiencies of mass-production techniques, large reductions in labor, formwork, and hardware costs can be realized. The precast prestressed structural and nonstructural concrete units are usually in production prior to and during site and foundation preparation work. This enhances the speed of construction as upper floor structural elements can be in production while site and foundation works are in progress.

By its production logistics, precast units usually have had substantial curing periods and significant time for initial shrinkage of the concrete material to occur prior to installation. Since the major structural and architectural components are inherently precured during precasting, the finished structure,

composed of integrated precast structural units with in-situ concrete, will be subjected to less shrinkage forces and consequential cracking damage in the

building frame.

Benefits- Precast structural units are usually designed to minimize temporary formwork and shoring. As a result, additional savings in construction time and costs can be realized. The overall savings in construction materials will have a significant impact on the environment. To manufacture one ton of cement, the power required involves the emission of approximately one ton of carbon dioxide (CO2) into the atmosphere, thus compounding the problem of global warming. Savings in construction materials would then mean a reduction in the total consumption of fossil fuels, for which the supply is diminishing rapidly. Cement and steel constitute the majority of the construction materials used in precast and prestressed concrete construction. Among principal construction materials, cement production is the third most polluting process, while steel production ranks higher than cement in terms of fuel consumption and CO2 emission.

The actual material savings can be analyzed by considering two basic structural elements: a typical floor slab and a typical floor beam sample. In the case of a conventional in-situ floor slab design, considerable savings in materials can be realized when a composite prestressed and precast slab system is used. For instance, when prestressed/precast construction is applied to a slab system spanning 8 m (26 ft) and designed to support a live load of 4 kPa (83.6 lb/ft2), a savings of 28% in concrete and 45% in steel materials can be realized . The environmental and natural-resource impact of this concept is very significant, especially since many millions of square meters of slab construction are in progress on the planet each day.

structures. Since gravitational and seismic loading forces are proportional to structure weight, a lighter weight building will enjoy additional reductions in

required structural sizes for all vertical and lateral force-resisting elements such as columns, beams, slabs, moment frames, shear walls, and foundation elements.

For high-rise buildings, a reduction in concrete sizes will also result in shallower structural concrete deck framing depths, which in turn will reduce the floor-to-floor height requirements and the overall height of the building structure. This will in turn reduce overturning resistance requirements under wind and seismic loading, while simultaneously lowering the cost of vertical elevator and stair shafts, mechanical and electrical risers, exterior façade cladding, and other vertical elements of construction. Prestressing usually is performed with special

high-tensile steels that provide maximum strength with a minimum quantity of steel, resulting in significant savings in steel tonnage and cost. Generally, the prestressing steel strength is approximately 4.5 times stronger than ordinary reinforcing steel, but costs only twice as much per unit weight as ordinary

reinforcing steel. Prestressing of beams and slabs is most economically applied in long-line precasting mass-production operations. Because of the inherent efficiencies of mass-production techniques, large reductions in labor, formwork, and hardware costs can be realized. The precast prestressed structural and nonstructural concrete units are usually in production prior to and during site and foundation preparation work. This enhances the speed of construction as upper floor structural elements can be in production while site and foundation works are in progress.

By its production logistics, precast units usually have had substantial curing periods and significant time for initial shrinkage of the concrete material to occur prior to installation. Since the major structural and architectural components are inherently precured during precasting, the finished structure,

composed of integrated precast structural units with in-situ concrete, will be subjected to less shrinkage forces and consequential cracking damage in the

building frame.

Benefits- Precast structural units are usually designed to minimize temporary formwork and shoring. As a result, additional savings in construction time and costs can be realized. The overall savings in construction materials will have a significant impact on the environment. To manufacture one ton of cement, the power required involves the emission of approximately one ton of carbon dioxide (CO2) into the atmosphere, thus compounding the problem of global warming. Savings in construction materials would then mean a reduction in the total consumption of fossil fuels, for which the supply is diminishing rapidly. Cement and steel constitute the majority of the construction materials used in precast and prestressed concrete construction. Among principal construction materials, cement production is the third most polluting process, while steel production ranks higher than cement in terms of fuel consumption and CO2 emission.

The actual material savings can be analyzed by considering two basic structural elements: a typical floor slab and a typical floor beam sample. In the case of a conventional in-situ floor slab design, considerable savings in materials can be realized when a composite prestressed and precast slab system is used. For instance, when prestressed/precast construction is applied to a slab system spanning 8 m (26 ft) and designed to support a live load of 4 kPa (83.6 lb/ft2), a savings of 28% in concrete and 45% in steel materials can be realized . The environmental and natural-resource impact of this concept is very significant, especially since many millions of square meters of slab construction are in progress on the planet each day.

In the case of conventionally designed reinforced concrete beams, significant savings in materials can also be realized by precasting and prestressing techniques.

For example, a precast and prestressed beam spaced at 4 m (13 ft) on centers and spanning 12 m (39 ft) and designed to support a load of 4 kPa (83.6 lb/ft2) can result in a saving of 60.8% in concrete and 66% in steel quantities over a conventionally designed un-prestressed beam cast in- situ supporting a similar span and loading .

Floating ocean platforms- Through innovation with precast and prestressed concrete, some latest trends are now focused toward the development and construction of floating ocean platforms used to extract minerals, energy, and other natural resources. Precast and prestressed concrete platforms have been constructed to support phosphate processing plants, floating liquefied propane gas (LPG) processing and storage facilities, and oil exploration platforms that are transported afloat and grounded for drilling.

For ocean platforms, the size and weight of prestressed and precast concrete construction will provide the greatest dynamic stability due to its large inertial advantage. Long-term durability of concrete construction in an ocean environment has been proven by actual service of existing prestressed precast concrete platforms over the last several decades. To exploit the greatest source of energy in the world, floating platforms for the support of ocean thermal energy conversion (OTEC) plants are also being planned with precast and prestressed concrete for the main hull structure. These plants will convert the difference in temperature between thewarmsea surface water and the cold deep ocean water [approximately 1000 m (3300 ft) depth] into electrical energy through a system of heat- transfer units and turbines. This warm sea surface water derives its energy from the Sun and is concentrated along the equatorial belt between the Tropic of Cancer and Tropic of Capricon girdling the Earth. Along this equatorial belt, the energy received daily from the Sun is equivalent to approximately 10,000 times the total amount of energy consumed worldwide in a day. The coldwater circulating about the deep ocean comes from the polar regions. This clean thermal energy source is literally inexhaustible, and prestressed precast concrete can play a major role toward its exploitation.

The energy derived from OTEC operations is developed in a closed-cycle system with no emissions or environmental pollution. This pure form of making energy can also be used to manufacture liquid hydrogen, a fuel highly regarded for its purity and considered as a possible replacement for fossil

fuels. The hydrogen fuel cell concept will produce electric power with no pollution, as the by-product of hydrogen-oxygen combustion is water. Hydrogen fuel cells can be used to power automobiles, buses, trucks, trains, power plants, ships, spacecraft, and many other vehicles and equipment. In theory, approximately two-thirds of the fossil fuels now used could be replaced by hydrogen-powered fuel cells.

Outlook. The economic and environmental benefits of precast and prestressed concrete can be significant if a coordinated engineering educational program in this regard is implemented. This educational program is critical and should extend worldwide with the cooperation of international bodies. The greatest impetus to such a program would be its economic benefit. When an economic advantage is available, it becomes very attractive to users who stand to benefit financially from cost and time savings. To maximize profits, owners and developers of a building project prefer to save as much cost and time as possible. The owner or developer would also likely prefer engaging architects and engineers who can provide these amenities of construction material—cost and time savings—assuming esthetic and functional requirements are equally met.

Architects and engineers worldwide may then be attracted to learning the tools of precast and prestressed concrete construction in order to meet the needs of owners and developers and enjoy added demand for their services. This could enhance greater use of methods that save construction material and time while actually preserving the environment and limited supply of natural resources. The entire construction and associated manufacturing industry, including its practicing professionals as well as governing bodies and academia, should explore known and yet-to-be-discovered methods of protecting the environment and natural resources by developing new technology. This would also include the development of renewable energy resources, new materials, as well as the recycling of existing materials in order to survive the anticipated material shortages and environmental problems of the future.