Grouting is the injection of pumpable materials into a soil or rock formation under pressure to change the physical characteristics of the natural formation.

Applications of Grouting

• Mainlines and Pipe Joints

• CIPP and Fold & Form Liners

• Slip Lining

• Point Repairs

• Lateral Sealing

• Manholes, Wet Wells and Lift Stations

• Tunnels

• Soil Stabilization

Grouting Materials

• Hydrophilic Foams

• Hydrophilic Gels

• Hydrophobic Foams

• Hydroactive Grouts

• Chemically Activated Gels

• Epoxies

• Acrylamide

• Acrylate

• Urethane

• Cementitious

Different Types of Grouting

Cementitious Grouting

• Injection of micro fine cements and mixing of Portland, soil and/or fly ash with chemical grouts for injection to eliminate infiltration and stabilize soil voids.

• Patented method of sealing leaks by compressing a fluid sealant of ultrafine cement between multiple everted tubes, forcing sealant into and through defects in pipe walls into soil voids. Flexible tube(s) are everted and inverted simultaneously in the pipe to allow a slug of sealant to migrate.

Annular Space Grouting

• Cementitious grouts to fill annular space between host pipe and liner

• Grouting of annular space between thermoplastic panel and spiral wound liners to stabilize liner

Chemical Grouting

The injection of a multicomponent chemical grout through pipe defects around the pipe to seal the leaks, fill voids and stabilize the ground around the structures.

Description: Two component chemical grouts mix within the void area created by the expansion of the packer and the inside pipe wall. The grouts are forced through the defects of the pipe and gel to fill voids, mix with the pipe bedding and surrounding soil. When mixed with the soil this gelled mass is no longer 10% or 20% solids but more like 99% solids.

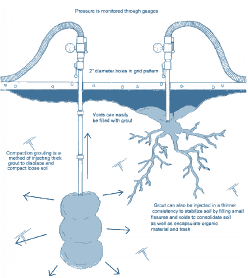

Pressure Grouting - A method of stabilizing or improving the density of a soil mass by filling in voids through injecting a mixture of cement, sand and soil under high pressure.

Applications

• Arresting Structural Settlement of existing Structures under floor slabs and footings.

• Pressure Grouting for cavities and fissures.

• Preventing collapse of Granular soils.

• Increasing soil strength and rigidity.

• Reducing/arresting ground movements.

• Filling voids, cracks fissures in natural rock formations.

• Curtain and compaction grouting for Dams and Reservoirs.

Geotechnical Considerations

Several conditions must exist in order for Pressure grouting to yield its best results:

• Grout hole Location and Geometry.

• Injection rates and Pressure.

• Grout Properties: liquid, transition, set.

• The grout injection rate should be slow enough to allow pore pressure dissipation.

• Sequencing of grout injection is also important. If the soil is not near saturation, grouting can usually be effective in most silts and sands.

• Soils that lose strength during remolding (saturated, fine grained soils; sensitive clays) should be avoided.

• Greater displacement will occur in weaker soil strata.Exhumed grout bulbs confirm that grouting focuses improvement where it is most needed.

• Collapsible soils can usually be treated effectively with the addition of water during drilling prior to grout injection.

Advantages of Pressure Grouting

• Pinpoint treatment

• Speed of installation

• Wide applications range

• Effective in a variety of soil and ground conditions

• Can be performed in very tight access and low headroom conditions

• Non-hazardous

• No waste spoil disposal

• No need to connect to footing or column

• Non-destructive and adaptable to existing foundations

• Economic alternative to removal and replacement of loose and low bearing soil

• Able to reach depths unattainable by other methods

• Enhanced control and effectiveness of in situ treatment with inflatable Packers

• Minimal impact to surface environment

• Low noise and vibration

Pressure Grouting Under Existing Foundation & Pressure Grouting Tools

Documentation During Testing and Sealing

• Identification of sewer line tested

• Pipe material, diameter and geographic location

• Location of each joint or service connection

• Test pressure used

• Pass or fail identification of joint

• Test pressure achieved & maintained for each joint passing

• Air temperature at time of testing

• Volume of grout placed per joint or service lateral connection

• Daily gel time checks

• Main line gel times generally should not be < 15 seconds

• Lateral gel times generally should not be < 25 seconds

• Weekly equipment pressure test results

Void Pressure Readouts

Void pressure readouts provide important data for operator and inspector

in determining grout necessary to effectively seal a leak.