Steel structures are important in a variety of land-based applications, including industrial (such as factory sheds, box girder cranes, process plants, power and chemical plants etc.), infrastructural (Lattice girder bridges, box girder bridges, flyovers, institutional buildings, shopping mall etc.) and residential sector. The basic strength members in steel structures include support members (such as rolled steel sections, hollow circular tubes, square and rectangular hollow sections, built-up sections, plate girders etc.), plates, stiffened panels/grillages and box girders. During their lifetime, the structures constructed using these members are subjected to various types of loading

which is for the most part operational, but may in some cases be extreme or even accidental.

Steel-plated structures are likely to be subjected to various types of loads and deformations arising from service requirements that may range from the routine to the extreme or accidental. The mission of the structural designer is to design a structure that can withstand such demands throughout its expected lifetime.

The structural design criteria used for the Serviceability Limit State Design (hereafter termed as SLS) design of steel-plated structures are normally based on the limits of deflections or vibration for normal use. In reality, excessive deformation of a structure may also be indicative of excessive vibration or noise, and so, certain interrelationships may exist among the design criteria being defined and used separately for convenience.

The SLS criteria are normally defined by the operator of a structure, or by

established practice, the primary aim being efficient and economical in-service

performance without excessive routine maintenance or down-time. The acceptable limits necessarily depend on the type, mission and arrangement of structures.

The structural design criteria to prevent the Ultimate Limit State Design (hereafter ermed as ULS) are based on plastic collapse or ultimate strength. The simplified ULS design of many types of structures has in the past tended to rely on estimates of the buckling strength of components, usually from their elastic buckling strength adjusted by a simple plasticity correction. This is represented by point A in Figure 7.1. In such a design scheme based on strength at point A, the structural designer does not use detailed information on the post-buckling behavior of component members and their interactions.

The true ultimate strength represented by point B in Figure 7.1 may be higher although one can never be sure of this since the actual ultimate strength is not

being directly evaluated.

In any event, as long as the strength level associated with point B remains

unknown (as it is with traditional allowable stress design or linear elastic design methods), it is difficult to determine the real safety margin. Hence, more recently, the design of structures such as offshore platforms and land-based structures such as steel

bridges has tended to be based on the ultimate strength.

The safety margin of structures can be evaluated by a comparison of ultimate

strength with the extreme applied loads (load effects) as depicted in Figure 1. To obtain a safe and economic structure, the ultimate load-carrying capacity as well as the design load must be assessed accurately. The structural designer may even desire to estimate the ultimate strength not only for the intact structure, but also for structures with existing or premised damage, in order to assess their damage tolerance and survivability.

Fig 1 Structural design considerations based on the ultimate limit state

In the structural design process, “analysis” usually means the determination of the stress resultants, which the individual structural members must be capable to resist.

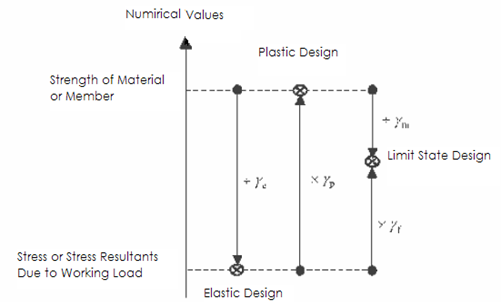

“Design” can mean the development of the structural layout, or arrangement of members, but it usually means the selection of sizes of members to resist the imposed forces and bending moments. Three methods of analysis are available, i.e. elastic analysis, plastic analysis and advanced analysis. Limit state design is a design method in which the performance of a structure is checked against various limiting conditions at appropriate load levels. The limiting conditions to be checked in structural steel design are ultimate limit state and serviceability limit state.Limit state theory includes principles from the elastic and plastic theories and incorporates other relevant factors to give as realistic a basis for design as possible.

Fig. 2 Level for different design methods at which calculations

are conducted (Commentary on BS5950 1 2000)

Ultimate Limit State Design of Steel Structures reviews and describes both

fundamentals and practical design procedures in this field. Designs should ensure that the structure does not become unfit / unserviceable for the use for which it is intended to. The state at which the unfitness occurs is called a limit state.

Figure 2 shows how limit-state design employs separate factors γf, which

reflects the combination of variability of loading γl, material strength γm and structural performance γp. In the elastic design approach, the design stress is achieved by scaling down the strength of material or member using a factor of safety γe as indicated in Figure 2, while the plastic design compares actual structural member stresses with the effects of factored-up loading by using a load factor of γp.

Special features of limit state design method are:

• Serviceability and the ultimate limit state design of steel structural systems and their components.

• Due importance has been provided to all probable and possible design conditions that could cause failure or make the structure unfit for its intended use.

• The basis for design is entirely dependent on actual behaviour of materials in

structures and the performance of real structures, established by tests and long-term observations

• The main intention is to adopt probability theory and related statistical methods in the design.

• It is possible to take into account a number of limit states depending upon the particular instance

• This method is more general in comparison to the working stress method. In this method, different safety factors can be applied to different limit states, which is more rational and practical than applying one common factor (load factor) as in the plastic design method.

• This concept of design is appropriate for the design of structures since any

development in the knowledge base for the structural behaviour, loading and materials can be readily implemented.