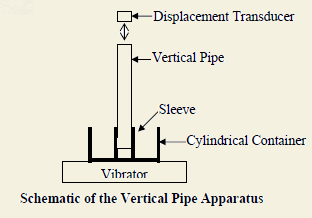

The vertical pipe apparatus (Tattersall and Baker 1989; Banfill, Yongmo, and Domone 1999) is a laboratory device which measures the effects of vibration on fresh concrete.

The device, which is depicted in Figure 1, consists of a 100 mm diameter, 700 mm long vertical pipe mounted above a metal cylindrical container that is attached to a vibrator. A sliding sleeve holds concrete in the pipe initially. A block attached to the container ensures that when the sleeve is lifted, concrete flows horizontally out of the pipe and is not blocked by concrete already in the cylindrical container. The block is 70 mm tall and the gap between the block and the pipe is 60 mm. To begin the test, the vibrator is started and the sleeve is lifted to allow concrete to flow out of the pipe. An ultrasonic displacement transducer above the pipe of concrete measures the height of the concrete in the pipe versus time. In older versions of the test, a tape measure was used to measure this distance.

The test is based on the principle that concrete behaves as a Newtonian fluid when subjected to vibration. The rate of flow of a Newtonian fluid in a vertical pipe is a function of the head, H, as shown in Equation [1], where b is the constant of proportionality expressing fluidity. The vibrator must be a simple wave-form vibrator with independent control of frequency and velocity. An inexpensive eccentric type or a common commercial vibrator would not allow the study of the effects of different vibration parameters on concrete.

Advantages:

• The vertical pipe apparatus is a dynamic test that provides valuable information on the flow of concrete under vibration.

• By changing the vibration parameters, the test can be used to determine values related to yield stress and plastic viscosity.

Disadvantages:

• The test is expensive and may not be appropriate for field use. The test does not provide a direct result.

• The 60 mm size of the opening below the pipe is too small for most aggregate sizes.

• For highly flowable concretes, the concrete will quickly flow out of the pipe without the assistance of vibration.